- Home

- Company

- Media Relations

- Blog

- Passive Fire Protection Execution

ENSURING EFFECTIVE EXECUTION OF PASSIVE FIRE PROTECTION AT YOUR SITE

An overview of survey and documentation

Fire protection is a critical consideration for architects, engineers and contractors responsible for creating the design, specification and construction of new buildings. It must also be considered in the ongoing maintenance of occupied spaces. Effective fire control within a building is generally achieved through a combination of active and passive fire protection systems.

Passive fire protection systems are integrated into the structure of a building, restricting the spread of smoke and fire to a compartment that is comprised of fire-rated walls, floors and ceilings. To the extent possible, all penetrations through these fire-rated walls, floors and ceilings should be fire stopped in accordance with a tested and approved system. Additionally, all bottom-of-wall, top-of-wall, and wall-to-wall joints in this fire-rated compartment should be fire stopped in accordance with a tested and approved system.

Preventing the spread of smoke and fire often presents challenges for consultants, installers, and end users alike. There is a lack of control mechanism on how the design of passive fire stop systems is effectively installed at a site.

Challenges faced for effective execution of passive fire protection

Due to differences in the level of awareness and understanding among different stakeholders, the adoption and enforcement of standards for the effective implementation of passive fire protection are not uniform.

Jobsites are often replete with uncertainties of applications which directly impact the selection and design of the fire protection system and in the process, the overall material estimation is also jeopardized.

A firestop solution will sustain the intended performance level if the selection and design are complemented by proper installation at the jobsite. One way to ensure the correct selection of system and installation is to adopt proper documentation while working at the jobsite.

Does our code talk about how to ensure the effective passive fire safety of your building?

NBC 2016 covers the concept of compartmentation for various applications which need to be fire stopped. It also covers how to carry out audits depending on the building height, who should conduct the audits and the frequency of audits.

IS12458:2019 is the Indian standard that talks about the integrity of the system, and the requirement of hose stream tests for through penetrations of penetrants like Ducts, Cables, Pipes, Bus bars etc.

Hilti has more than 1,000 tested systems that cater to firestopping solutions for joints and through penetrations applications in accordance with globally accepted standards like ASTM E814 (UL 1479) for through penetrations and ASTM E1966 (UL 2079) for joints.

How to ensure that the installed system will perform?

A Product is only as good as the installation that has been done. It’s never been easier to plan and document every stage of a firestop project such as pre and post installation pictures, UL listing and system certificate, Engineering judgement etc. in a single document which also includes all the relevant stakeholders.

Hilti has come up with services to provide pre and post installation documentation known as ON!Site Survey and ON!Site Documentation. These comprehensive services allow planners, building owners and their teams to simply and more efficiently document firestop surveys and installation, as well as produce installation reports with a single click of a button. Hilti Documentation Manager software- CFS DM is used for these services to get more reliable, efficient, and compliant firestop installation, and documentation from start to finish of the project.

Firestop ON!Site Services

ON!Site Survey

Covers activities such as surveying openings to provide accurate UL solution and product estimations. It covers features of penetration and joint details such as the size of the opening, type and no. of penetrants, application location and image before installation. As a service output, it provides estimation as per the survey, BOQ text, Technical submittals, UL listing and system certificate, application methodology, floor and wall plan drawing, commercial offer, service disclaimer and terms & conditions.

ON!Site Documentation

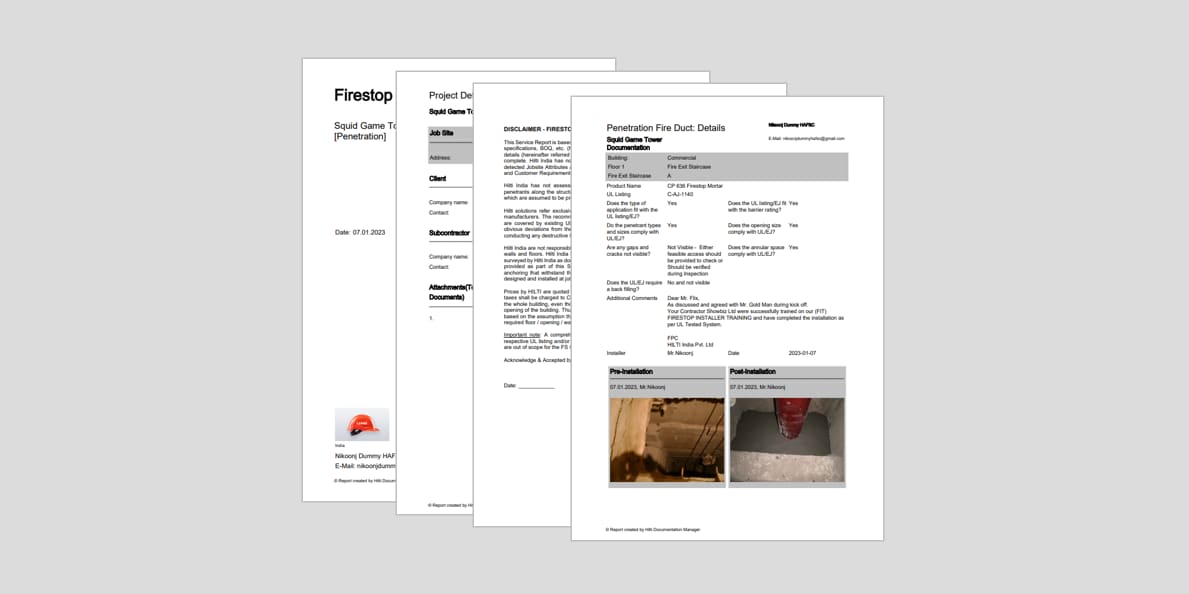

Offers a professional report to simplify the audit process influenced by NBC 2016 and assurance of installed quality. It covers features such as a filled pre-defined checklist on adherence to UL systems & EJ’s, application location and image after installation and improvement recommendations.

Service output covers report with installed firestop products including checklists based on visual checks, application pictures, floor/wall plan drawings & handing over certificates/documents.

Three easy steps for effective ON!Site Survey & ON!Site Documentation

Hilti’s Documentation Manager is a cloud-based system that provides a simpler, easier-to-use process for documenting, tracking, and maintaining the fire barrier integrity of your facility.

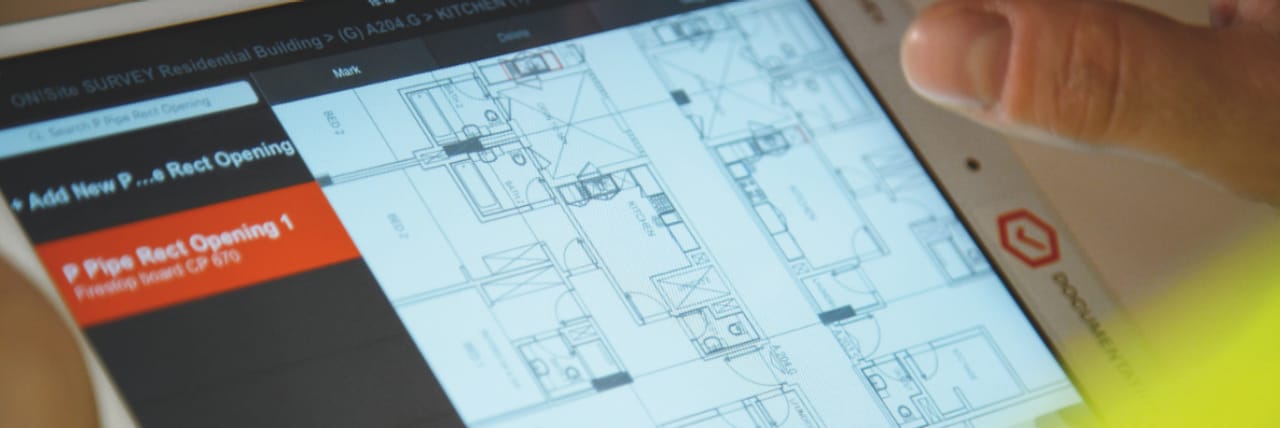

Step 1: The software offers a highly intuitive, web-based back office interface in which customers can edit, create and manage projects, upload technical documents, 2D drawings and floorplans, assign users and create custom project attributes.

Step 2: Using a mobile device, it is easy to document Firestop penetrations or even other categories throughout the facility. Pictures can be taken and synchronized automatically, while markers can be set on the uploaded floor plan for easy identification of all penetrations or other applications. Optionally, identification stickers at each penetration can be placed to quickly identify all penetration details.

Step 3: After completion of the project, a report can be created in either PDF or Excel format. This can also be used as an intermediate work status report. Users can even personalize reports by utilizing customized attribute filters.

Project report with all documented details, including pictures, approval documents and floorplan location.

Conclusion

For effective performance of Passive firestop system, it is imperative that the system be installed properly as per the tested system design. This can be achieved by proper documentation of installed fire stop systems both pre and post installation.